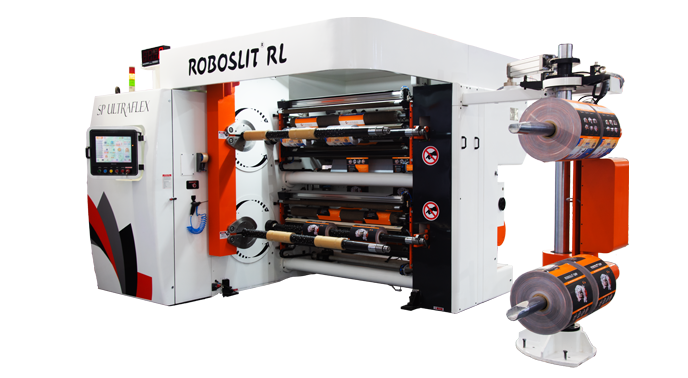

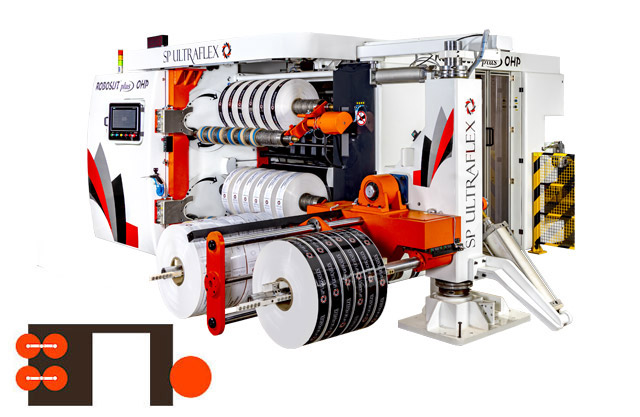

ROBOSLIT ® RLDual Turret Rear Loading Slitter Rewinder

The ROBOSLIT ® RL (Rear Loading) dual turret slitter rewinder is a compact, rear loading machine with a dual turret rewind section that permits changeovers within 26 seconds, resulting in significantly higher outputs as compared to its duplex counterpart.

Technical Specification

| Position , type of unwind | Rear, integral |

| Maximum web width | 1300 mm (upto 1650 mm on request) |

| Maximum unwind diameter | 1000 mm |

| Unwind core inner diameter | 76 mm and 152 mm |

| Maximum rewind diameter | 600 mm |

| Rewind core inner diameter | 76 mm |

| Minimum slit width | 50 mm (30 mm on request) |

| Layon displacement | Horizontal |

| Layon actuator | Pneumatic piston |

| Rewind splicing | Automatic |

| Tension management | Automatic, intelligent (ITM™) |

| Job setup | Manual |

| Turret structure | Cantilevered |

| Static management | Static elimination |

| Maximum machine speed | 800 m/min |

| Rewind change-over time | 26 Seconds |

| Materials handled | Plastic films, flexible packaging laminates |

Optional Features

| Shear cutting mode – tangential, for paper and aluminum foil based laminates | |

| Electro-mechanical, linear floor lift for unwind reel | |

| Motorized ejector for displacing the rewind reels on to the off loader | |

| Auto off loader to bring the ejected reels to waist level for easier removal | |

| Trim winding unit for the compact accumulation of trim waste | |

| Rewinding on 152 mm/ 70 mm ID rewind cores | |

| Additional safety devices | |

| CCTV | |

| SCADA |